Service

Since the 90th ELPIDA has been an expert supplier for several of wastewater treatment plant covering many wastewater problems.

ELPIDA generally provides all process steps employed in wastewater technology today. Selected steps will be combined to offer the ideal overall solution for any kind of wastewater problem or process water problem in industry or municipality.

Water treatment technology types

Primary Treatment

Removal of solids which results in reduction of pollution load in your wastewater. Depending on your effluent you might require a screen, a flotation system or a flocculation & flotation system. If you discharge your water into a sewage system a primary treatment can be sufficient to meet the effluent requirements for treatment of water.

Secondary Treatment

Step, biological treatment. System can select the most economic treatment system for you based on your type of wastewater, based on the actual requirements and local circumstances.

Tertiary Treatment

Polishing, due to very tight requirements. Effluent after a tertiary treatment step is very clean, so clean that the step to reuse of your water can be made.

Sludge Dewatering

During treatment of wastewater and wastes, sludge is produced which needs to be disposed of in order to diminish the disposal costs.

Products

The wastewater process using the following products to achieve the treatment wastewater needs.

Screen Types: The first operation in wastewater treatment is screening, where coarse solids are filtered from the influent. We have different types of screens depends about application.

Screen Types:

- Bar Screen: Inclined Bar Screen is a robust machine designed for heavy duty screening at the head of works in a sewage wastewater processing plant. The screen is a fine screen, which is located in the direct flow of the main inlet channel.

- Curved Screen: For separation of solids from liquids. Self-cleaning. No motor power need. Useful in various industry sectors, where it can: filter, separate, clear up, condense, collect, classify, dehydrate. Necessary for the primary treatment of civil, industrial agriculture wastewater.

- Drum screen: The Drum Screen is used for the micro screening of solids from wastewater for a variety of application.

Sand Separators: Separation of settling solids from wastewater and process water by means of sedimentation. It is used for separation and washing of sands present in the water. Water enters in the hopper where solid particles are separated and decant on the bottom.

Pipe Flocculators: constitute an ideal mixing solution for the physicmical treatment of wastewater. These pipe flocculators are equipped with injection points for chemicals, a connection point for pH-measurement and sampling taps, enabling monitoring of every single important step in the entire process.

Dissolved Air Flotation System (DAF): The flotation units are used to separate fats, oils, suspended substances and flakes (originating from physicochemical Or biological treatment). By introducing a flow of air saturated water under pressure, micro air bubbles are formed in the flotation. These bubbles attach themselves to the impurities to help them float to the surface, where a skimmer removes them.

Biological Treatment Systems: The mainly soluble organic matter is removed by biological treatment. Biomass converts organic matter to water, carbon dioxide and new biomass with the aid of oxygen.

SBR Treatment System: Sequencing Batch Reactor) with a high purification efficiency. These installations are used for the treatment of major water flows on a limited surface area. The great advantage lies in the fact that a constant amount of water is being processed at all times, regardless of the amount of water that is being supplied. As a consequence, the discharge values are constant all times. The entire process is monitored and controlled via a PLC.

MBR Treatment System: MBR is an advanced wastewater treatment technology, which combines membrane separation with biological wastewater treatment. A typical MBR treatment system is made up of three parts, an anoxic zone (where there is no or a very low concentration of oxygen), aerobic zone (where oxygen is present) and membrane separation. Wastewater is pumped into the anoxic tank and is recirculates between the anoxic and aerobic tanks. Different types of microbes grow under the anoxic and aerobic conditions, which are responsible for breaking down various contaminants present in the wastewater.

Sludge dewatering Systems: Decanter centrifuges play a crucial role in removing the water content from sludge from wastewater plants, as well as from industrial waste streams. The drier the sludge, the smaller its volume and the lower its weight, both of which significantly reduce disposal and transport costs.

Dosing Makeup unit: Polymer preparation and dosing systems for the preparation of stock solutions or working solutions of synthetic flocculants (polyelectrolytes).

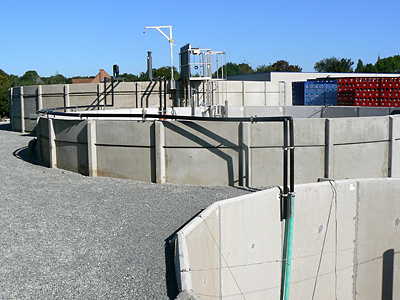

Waste Water Treatment Plant

- Screening

- Material Handling

Fluid Control

Grit Removal

Clarifiers and Settling

Aeration Systems

Biological Treatment

- Sludge Treatment

Do You Have A Construction Project We Can Help With?

In every waste we see opportunity.